The Textile of Tomorrow

since 1985

Our approach to innovation is bold and disruptive, driven by a constant commitment to progress. We take risks whenever we identify a more efficient, sustainable, and transformative way to serve our clients, the planet, and a fashion industry with purpose. Our goal? To deliver the most inspiring experience possible.

Founded in 1985 in Portugal, Acatel Acabamentos Têxteis S.A. has grown from a small company into an international reference in the sector. Known for its excellence, innovation, and commitment to sustainability, Acatel blends tradition with modernity, offering finishing solutions that elevate quality and design to a new level.

What we are capable of

At Acatel, continuous dyeing is synonymous with efficiency, precision, and chromatic consistency. Using advanced technologies, we ensure every fiber of the fabric absorbs the dye uniformly, resulting in homogeneous, long-lasting, high-quality color. This continuous method enables fast and reliable production, ideal for large fabric volumes.

Continuous dyeing is the perfect solution for large-scale production, combining speed, precision, and efficiency. At Acatel, each step of the process—from fabric preparation to dye application—is managed by a highly specialized team, ensuring consistent and top-quality results. This method optimizes resources, reduces waste, and guarantees a superior, long-lasting finish.

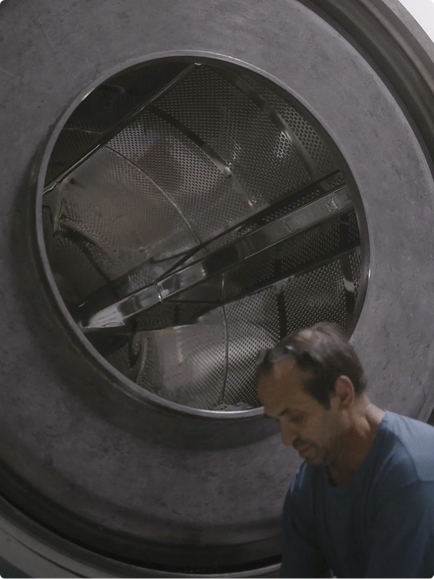

At Acatel, garment dyeing means customization and creativity. With a wide color palette and various available effects, each piece is transformed to meet the client's specifications, resulting in unique and exclusive products. This flexible process enables the creation of tailor-made designs that align with market trends and brand identity.

Using innovative techniques, Acatel ensures maximum quality and durability of dyed garments. High-performance dyes and advanced dyeing processes produce vibrant colors that are wear-resistant and colorfast. Our highly skilled team is committed to delivering products that exceed the highest quality standards.

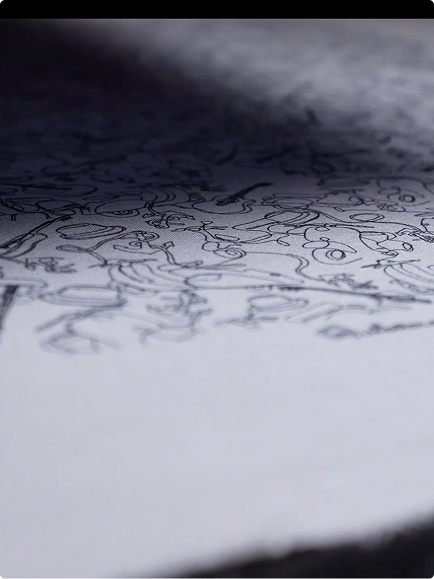

Acatel’s conventional printing stands out for its versatility and outstanding results. Techniques such as screen printing, rotary, and flatbed allow for highly detailed, durable designs. Each method offers unique possibilities, adapting to each client’s creative vision and delivering vibrant, high-quality patterns.

Ideal for large-scale production, this method offers high capacity and efficiency. With modern, technologically advanced infrastructure, Acatel executes large-scale projects with speed, precision, and rigorous quality control at every stage. The team’s expertise ensures a final product that meets the industry's highest standards.

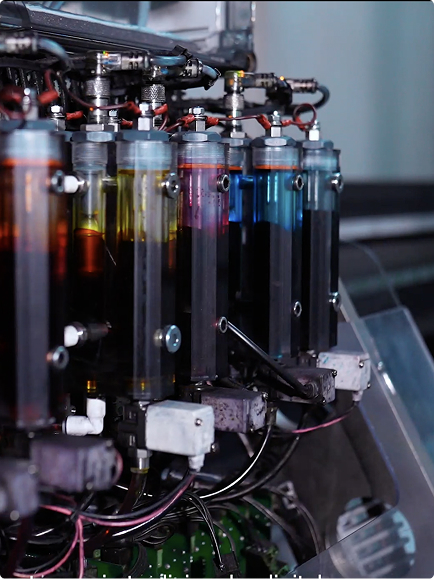

Acatel’s digital printing combines speed, precision, and personalization. This process allows for exclusive, high-resolution designs with vibrant colors and sharp details, easily adapting to the specific needs of each client. Ideal for on-demand production, digital printing ensures agility, flexibility, and efficiency in every project.

Perfect for short runs and on-demand production, this process excels in efficiency, sustainability, and adaptability. Digital printing ensures precise resource management, reduced waste, and the use of eco-friendly inks. This flexible technology enables fast and customized adjustments to meet market demands.

At Acatel, finishing is a key step in enhancing the performance and quality of textiles. Through sustainable and technical treatments, we improve softness, durability, and appearance, delivering results that meet the highest industry standards. This process reflects our ongoing commitment to innovation, functionality, and excellence in every detail.

Acatel offers a wide range of finishes tailored to the specific needs of each client. From functional solutions that enhance fabric performance to aesthetic treatments that improve appearance, every step is developed with precision and care. Our commitment to quality and customer satisfaction is embedded in every detail of the finishing process.

Acatel is a reference in textile finishing, dyeing, and printing, offering innovative and sustainable solutions for fashion brands and the global textile industry. Our services include digital and traditional printing, high-performance meter dyeing, piece dyeing, and technical finishes that ensure quality and differentiation for textiles.

Acatel continuously invests in eco-friendly technologies, such as natural pigments, low-energy consumption processes, and water optimization and reduction systems. Additionally, we follow strict environmental and social standards throughout all stages of production.

Yes, Acatel is certified by several international organizations, including Bluesign, GOTS, Global Recycled Standard, OEKO-TEX, ISO9001, ISO14001, HiggIndex FEM/FSLM, and ZDHC. These certifications ensure compliance with environmental, social, and quality standards in our production.

We offer digital and traditional printing (reactive, burnout, devoré, glitter, dispersed, among others), always with the highest precision and durability.

Our dyes include sustainable processes and innovative solutions that reduce chemical and water consumption. Our finishes incorporate soft-touch technologies, thermoregulation, and customized technical performance for different applications.

Yes, we use innovative solutions such as Recycrom, Algaeing Algadye, Bioblack TX, and Living Ink, which provide vibrant colors with minimal environmental impact.

Yes, we offer an exclusive print development service, ensuring customized designs aligned with market trends.

Clients can request samples by contacting us via email. The availability of textile bases depends on third-party approval and requires minimum quantities for production.

We work with brands of all sizes, from sustainable start-ups to large textile companies, adapting our processes to meet each client’s specific needs.

Yes, we participate in textile industry events, including Première Vision Paris in the Smart Creation sector, where we showcase our innovative and sustainable processes and technologies.

Social Responsability

Sustainability, commitment, and action.

Committed to social and environmental responsibility, Acatel has positioned itself as a leader in sustainable textile practices. Through innovative technologies such as Colorifix and the Pigmentura system, we significantly reduce the consumption of natural resources while enhancing finishing quality.

Among the decarbonization initiatives, we highlight the installation of a biomass boiler and solar panels—measures that contribute tangibly to reducing our carbon footprint.

People are also a priority. The company promotes the continuous development of its employees, offering training, safety, and an inclusive work environment. We maintain close, ethical relationships with partners and suppliers, ensuring that our entire production chain meets high standards of quality and sustainability. By uniting tradition and innovation, Acatel is building a more responsible future and remains at the forefront of the sustainable transformation of the textile industry.